Products

GEM develops powerful toolkits to address complex engineering issues.

CB2ATA

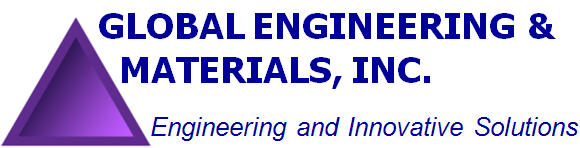

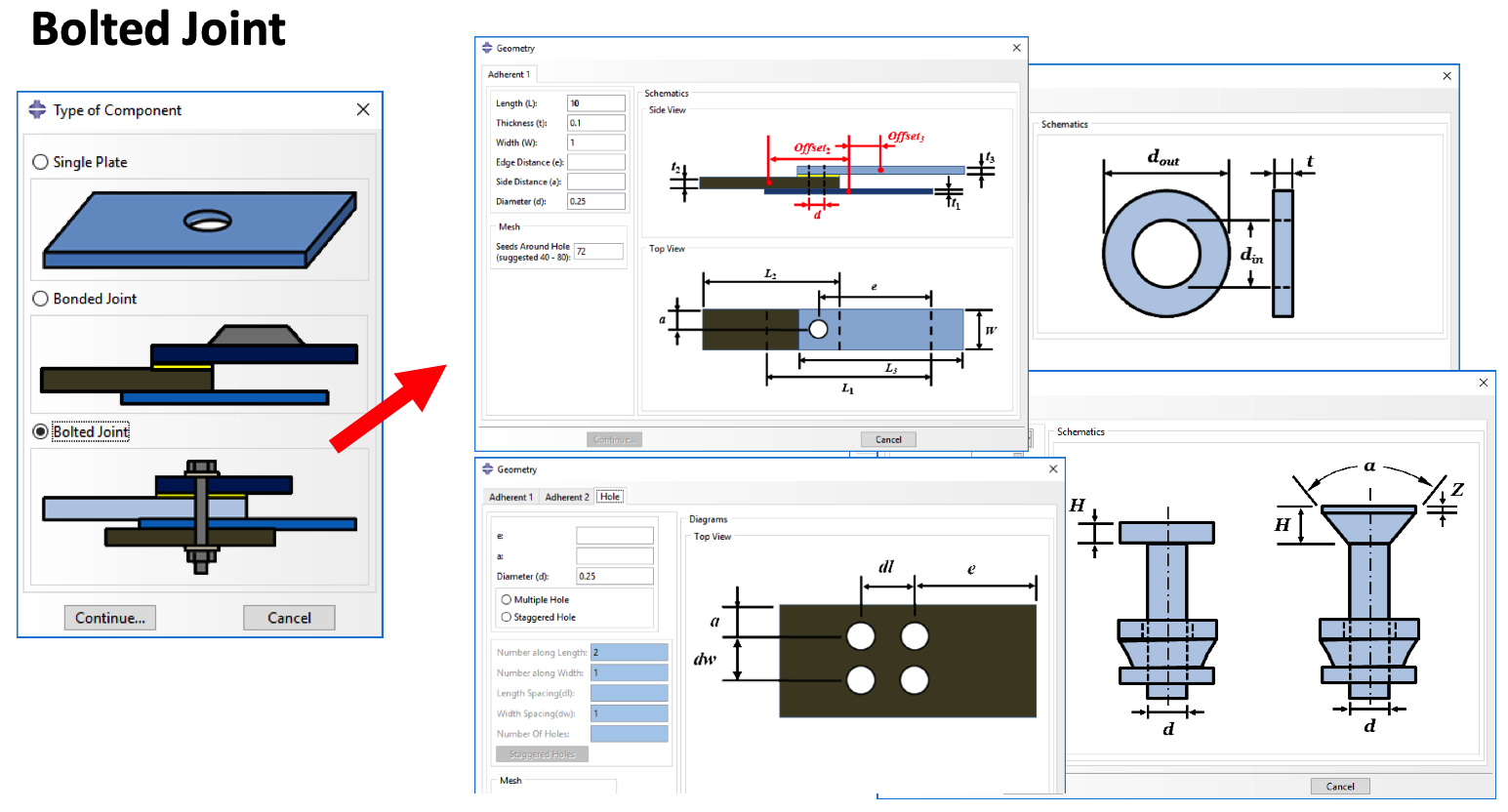

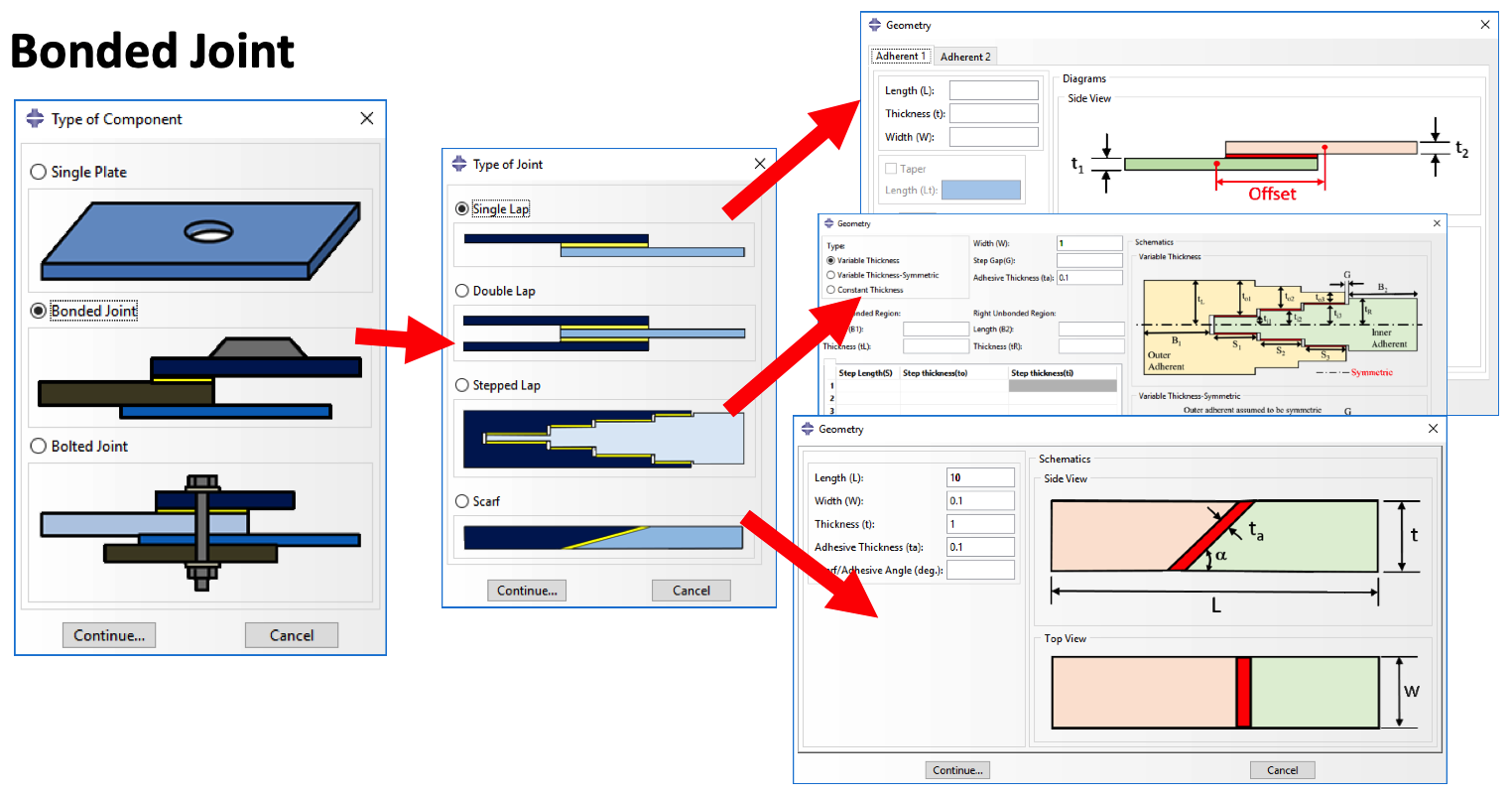

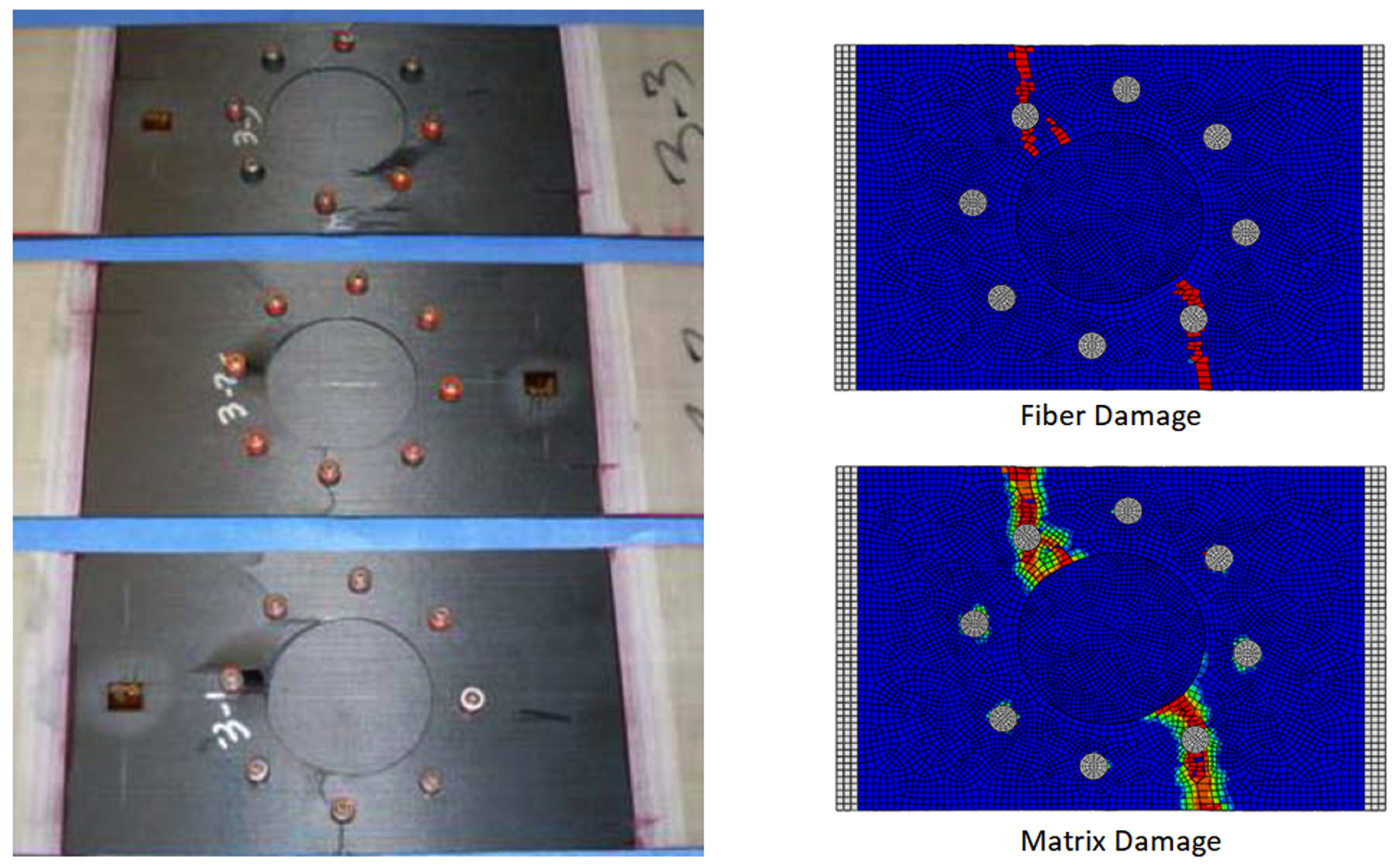

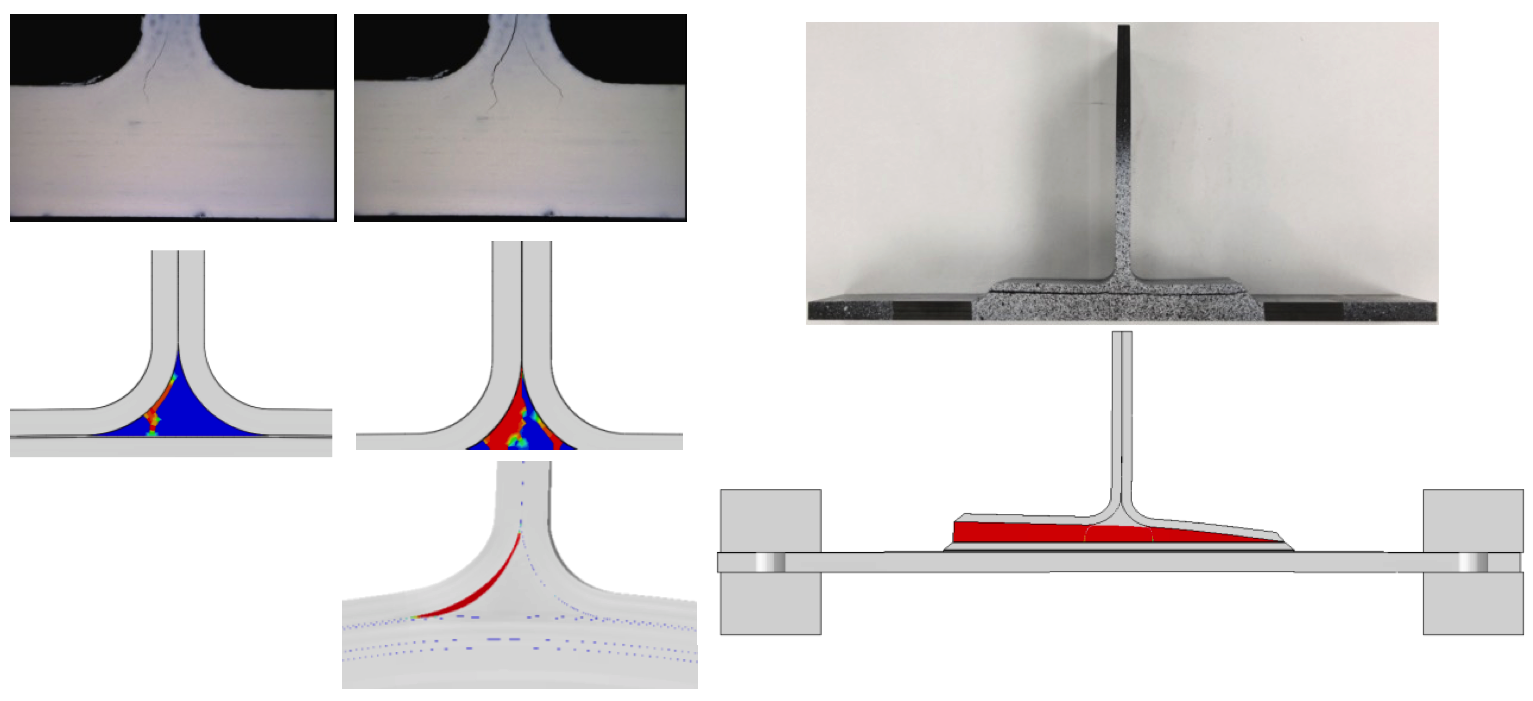

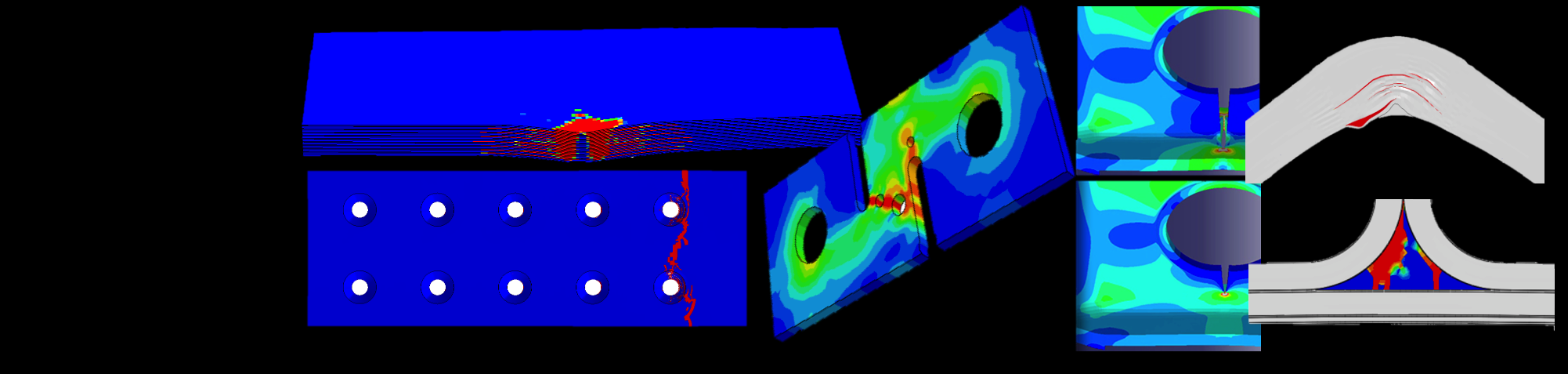

Composite Bolted and Bonded Analysis Toolkit for Abaqus (CB2ATA) is an add-on on toolkit for Abaqus’ implicit solver to perform progressive failure analysis of Bolted, Bonded and Bolted/Bonded composite joints. Two modules, one for bolted joints and the other for bonded joints, have been developed in two separate Small Business Innovative Research (SBIR) efforts. The capability of CB2ATA’s discrete crack network (DCN) approach and discrete crack informed continuum damage modeling approach has been demonstrated via their blind predictions of static and fatigue damage evolution under AF’s Tech Scout 1 program. Its capability has also been verified and validated for failure prediction of a protruding bolted component under static loading, a bonded T-stiffener under static and fatigue loading and a bonded helicopter flexible beam. Further capability extension and validation studies are being performed under the NAVAIR sponsored programs for a full-scale composite wing section subjected to a representative aircraft loading. Under the Phase III program, the toolkit has been targeted to support the sustainment of composite structural components with the fabrication and service induced defects. Built-in case wizard is created for model generation and response and failure prediction of bonded and bolted joints of various configurations.

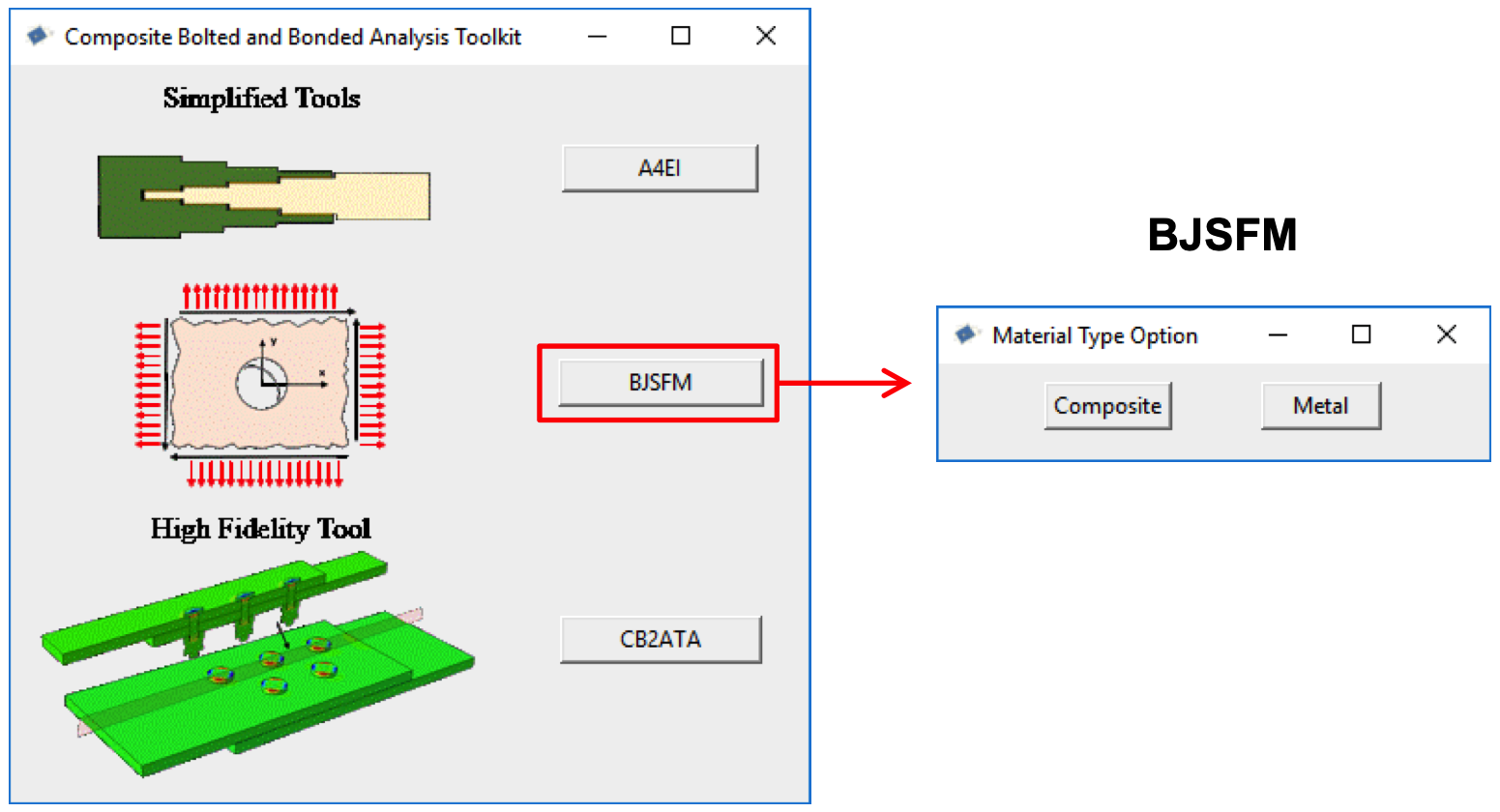

Given a large amount of coupon tests needed to generate correction factors for simplified analysis tools for bolted joints (BJSFM) and bonded joints (A4EI), a high fidelity tool such as CB2ATA has been used as a virtual testing tool to generate the correction factors that could be anchored by limited tests at the corners of the design space. An interface of the CB2ATA tool with BJSFM and A4EI is established to use the calibrated model parameters from the virtual testing tool (CB2ATA) for simplified analysis. Such an interface creates a great versatility in transferring the model parameters between the high fidelity tool and the simplified tools.

Verification and validation studies have been performed to demonstrate the applicability of the CB2ATA toolkit for the bolted and bonded repair of composite components with complex geometry and loading conditions such bolted repair, composite Tee joint, and cruciform specimens under multiaxial loading.